The XNX Universal Transmitter, designed by Honeywell Analytics, offers flexible integration, simple installation, and user-friendly operation. It supports various gas sensing technologies, ensuring reliable performance across diverse applications.

1.1 Overview of the XNX Universal Transmitter

The XNX Universal Transmitter is a versatile and advanced gas detection system designed for use with Honeywell Analytics’ wide range of gas sensing technologies. It supports both toxic and flammable gas detection, offering flexibility in various industrial applications. The transmitter is engineered for seamless integration into existing systems, ensuring reliable performance and ease of operation. Its robust design allows for installation in diverse environments, from hazardous areas to standard industrial settings. With a focus on simplicity and efficiency, the XNX transmitter is ideal for applications requiring precise gas monitoring, alarm management, and data communication. It is compatible with multiple sensor types, including catalytic bead, infrared, and electrochemical technologies, making it a comprehensive solution for gas detection needs.

1.2 Key Features and Benefits

The XNX Universal Transmitter offers a range of key features that enhance its functionality and user experience. Its universal compatibility with various gas sensing technologies provides flexibility in application. The transmitter features a ruggedized design with threaded ports in metric or NPT versions, ensuring installation flexibility. It also supports multiple power supply configurations, accommodating different system requirements. The XNX is designed for ease of use, with straightforward installation and maintenance processes. Its advanced grounding and intrinsic safety features ensure safe operation in hazardous environments. Additionally, the transmitter’s ability to configure gas type, range, and alarm levels allows for tailored settings to meet specific application needs. These features make the XNX a reliable and adaptable solution for gas detection systems, ensuring accurate monitoring and efficient performance across various industrial settings.

1.3 Structure of the Installation Manual

This manual is organized into clear sections to guide users through the installation and operation of the XNX Universal Transmitter. It begins with an introduction to the transmitter, followed by pre-installation requirements, installation steps, and configuration details. The manual also includes sections on maintenance, troubleshooting, and compliance with regulatory standards. Appendices provide technical specifications, a glossary of terms, and a troubleshooting guide. Each chapter is designed to address specific aspects of the transmitter’s setup and use, ensuring a comprehensive understanding for safe and effective operation. The structured format allows users to easily navigate through the document, accessing the information they need at each stage of the process. This clear organization ensures that all necessary details are covered, from initial setup to ongoing maintenance.

Pre-Installation Requirements

Review the manual thoroughly, ensure all tools and materials are prepared, and verify the site meets environmental and safety standards before proceeding with installation.

2.1 Safety Precautions and Warnings

Ensure all safety protocols are followed to prevent accidents. Never open the XNX enclosure under power unless the area is confirmed non-hazardous. Proper grounding is essential for intrinsic safety. Use only certified M25 cable glands for installation. Always refer to the technical manual (1998M0738) before starting. Adhere to local and international safety standards. Shielded, armored cables must be used to maintain safety and performance. Avoid exposing the transmitter to extreme environmental conditions beyond its rated specifications. Ensure the sensor is properly earthed to prevent electrical hazards. Follow all warnings and cautions outlined in the manual to guarantee safe and reliable operation. Failure to comply may result in system malfunction or personal injury. Always power down the unit before performing any maintenance or repairs.

2.2 Tools and Materials Needed

To ensure a smooth installation, gather the necessary tools and materials. Required tools include a screwdriver, wrench, and multimeter for wiring and connections. Use only certified M25 cable glands for secure and safe cable entry. Armored or shielded cables are recommended to maintain signal integrity and protection. Ensure compatibility with metric or NPT threaded ports. Additional materials may include grounding wires and appropriate seals for environmental protection. Refer to the technical manual (1998M0738) for specific requirements. Always use Honeywell-approved components to guarantee compliance with safety and performance standards. Proper tools and materials are essential for a reliable and safe installation. Adhere to the manual’s guidelines to avoid installation errors and ensure optimal transmitter functionality.

2.3 Site Preparation and Environmental Considerations

Ensure the installation site meets all safety and environmental requirements. Choose a location that minimizes exposure to extreme temperatures, humidity, and corrosive substances. Verify the area is non-hazardous before opening the transmitter enclosure. Proper ventilation is essential to prevent gas accumulation. Avoid installing in areas with explosive atmospheres unless intrinsic safety measures are in place. Grounding is critical for electrical safety and intrinsic safety compliance. Use appropriate seals and protective measures to maintain environmental ratings. Ensure power supply compatibility and configure wiring to avoid interference. Site preparation must comply with local regulations and standards. Plan for future maintenance access and ensure the location is easily reachable. Environmental considerations are vital for reliable operation and longevity of the XNX transmitter. Always follow the technical manual guidelines for specific site requirements. Proper site preparation ensures safe and efficient installation. Adhere to all safety and environmental standards for optimal performance.

Installation Process

The XNX transmitter installation involves a streamlined process, including unpacking, mounting, sensor connection, wiring, and system testing. Follow safety guidelines and technical specifications for a successful setup.

3.1 Unpacking and Inspecting the Transmitter

Begin by carefully unpacking the XNX transmitter, ensuring all components are included and undamaged. Inspect the transmitter unit, mounting hardware, power cables, and documentation. Verify the presence of the technical manual, which provides detailed installation and safety guidelines. Check for any visible damage or tampering that may have occurred during shipping. If any discrepancies are found, contact Honeywell Analytics support immediately. Before proceeding, ensure the transmitter is powered down and the area is safe for handling. This step is critical to ensure a smooth installation process and prevent potential safety hazards. Always refer to the technical manual for specific instructions and precautions during unpacking and inspection.

3.2 Mounting the Transmitter

The XNX transmitter offers flexible mounting options to suit various installation requirements. It features five threaded ports, available in both metric and NPT versions, providing versatility for different setups. Ensure the transmitter is mounted securely to prevent vibration or movement, which could affect performance. Refer to the technical manual for specific mounting instructions and safety precautions; Always follow local installation standards and ensure the area is safe and non-hazardous before proceeding. Proper grounding of the transmitter is essential for intrinsic safety and electrical integrity. Use only certified M25 cable glands and shielded, armored cables as specified in the manual. This ensures reliable operation and compliance with safety regulations. Mounting should be done by trained personnel to avoid any potential risks or damage to the equipment.

3.3 Connecting the Sensor to the Transmitter

Connecting the sensor to the XNX transmitter requires careful attention to ensure proper functionality and safety. Begin by preparing the sensor according to the manufacturer’s instructions, ensuring compatibility with the transmitter. Locate the designated sensor ports on the transmitter and connect the sensor cables securely, following the wiring diagram provided in the technical manual. Ensure all connections are tight to prevent signal loss or interference. Proper grounding of the sensor is critical for intrinsic safety and to avoid electrical noise. Refer to the manual for specific grounding procedures and safety guidelines. After connecting, verify that the sensor is recognized by the transmitter and that all configurations are set correctly. Always follow safety precautions, such as ensuring the area is non-hazardous before connecting or powering up the system. This ensures reliable operation and compliance with safety standards.

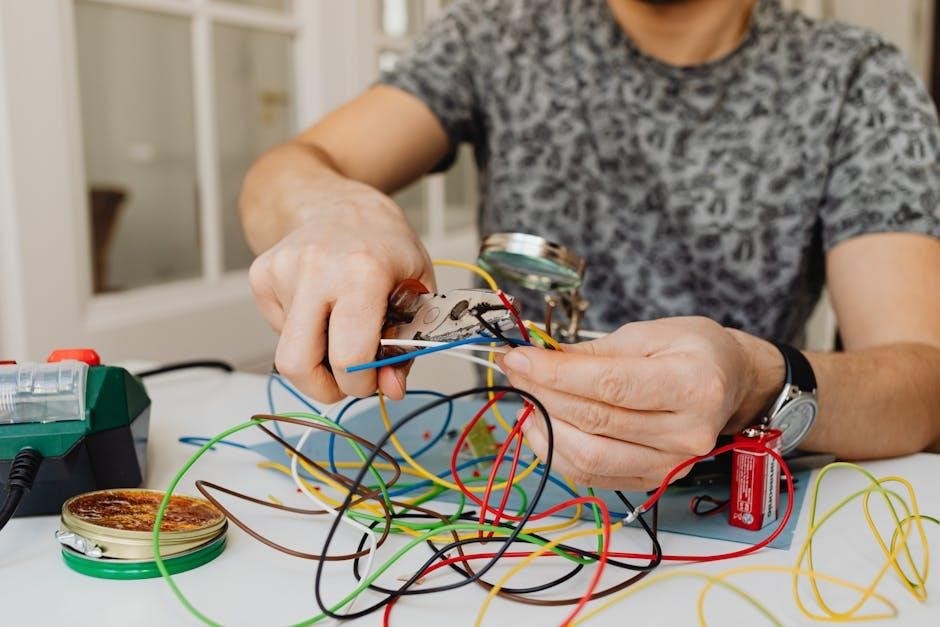

3.4 Wiring and Power Supply Configuration

Proper wiring and power supply configuration are critical for the XNX transmitter’s operation. Begin by connecting the power supply, ensuring it meets the transmitter’s requirements (typically 24V DC). Use shielded cables to prevent electromagnetic interference (EMI). Connect the power supply wires to the designated terminals on the transmitter, ensuring polarity is correct. Next, configure the wiring for any additional components, such as relays or communication modules, according to the technical manual. Verify all connections are secure and meet intrinsic safety standards. Ground the system properly using certified cable glands to ensure electrical safety. After wiring, power up the transmitter and test all functions to confirm correct operation. Always refer to the safety manual for specific precautions and adhere to local electrical codes. Proper configuration ensures reliable performance and compliance with safety standards.

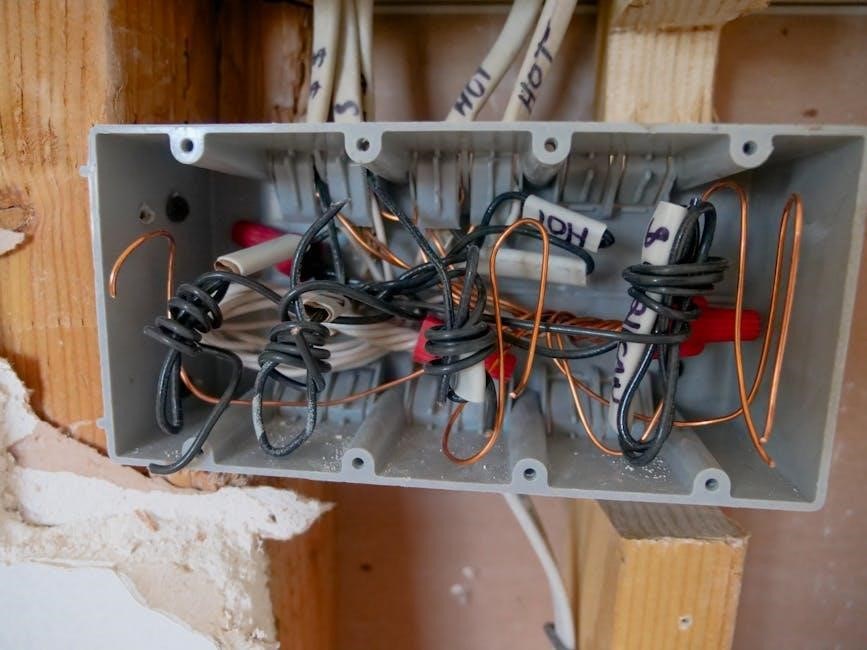

3.5 Grounding and Intrinsic Safety Considerations

Proper grounding and intrinsic safety are essential for safe and reliable operation of the XNX transmitter. Ensure the transmitter and sensor are correctly earthed using certified cable glands, such as M25 types, to maintain intrinsic safety. This prevents electrical hazards and ensures compliance with safety standards. Avoid opening the transmitter enclosure while it is powered unless the area is confirmed to be non-hazardous. Grounding must be done in accordance with local electrical codes and the transmitter’s safety manual. Use shielded and armored cables to prevent interference and ensure all connections are secure. Regularly inspect grounding points to prevent corrosion or damage. Always follow the manufacturer’s guidelines for intrinsic safety to protect against ignition risks in hazardous environments. Proper grounding ensures the system operates safely and efficiently. Consult the technical manual for detailed procedures and safety precautions. Grounding is critical for maintaining the integrity and safety of the XNX transmitter system.

Configuration and Setup

Configuration involves setting gas type, range, alarm levels, and relay outputs. Calibration ensures accuracy, while testing confirms system functionality. This process ensures reliable and safe operation of the transmitter.

4.1 Configuring the Transmitter for Gas Type and Range

Configuring the XNX transmitter involves setting the gas type, range, and alarm levels. This ensures the transmitter operates accurately for the specific gas being monitored. Refer to Section 4.1 for detailed instructions. The gas type must match the sensor installed, and the range should be set according to the expected gas concentration. Proper configuration is critical for reliable performance and safety. Ensure the transmitter is grounded for intrinsic safety. Always follow the technical manual for specific settings and guidelines to avoid errors. Improper configuration can lead to inaccurate readings or safety hazards. Use certified tools and consult the troubleshooting guide if issues arise during setup. Adhere to the safety precautions outlined in the manual to ensure a secure and functional system.

4.2 Setting Alarm Levels and Relay Outputs

Setting alarm levels and configuring relay outputs is essential for ensuring the XNX transmitter responds appropriately to gas detection thresholds. Alarm levels must be set according to the specific gas type and safety requirements, with low and high alarm thresholds defined. Relay outputs can be configured to trigger alarms, activate warning systems, or interface with external control systems. Proper configuration ensures timely alerts and responses to hazardous conditions. Refer to the technical manual for detailed instructions on setting these parameters. Use certified tools to avoid errors, and test the configuration to confirm functionality. Accurate setup of alarm levels and relays is critical for maintaining safety and reliable monitoring. Always follow the guidelines provided in the manual to ensure optimal performance and compliance with safety standards.

4.3 Calibrating the Sensor

Calibrating the sensor ensures accurate gas detection and transmitter performance. Begin by performing a zero calibration in a clean, gas-free environment to set the baseline. Next, conduct a span calibration using a certified gas mixture specific to the sensor type. Follow the manual’s instructions for gas type and range configuration. Use only approved calibration tools and gases to maintain precision. After calibration, verify the sensor’s response and adjust if necessary. Regular calibration, typically every 30 days, is essential for maintaining reliability. Always ground the sensor during calibration to ensure intrinsic safety. Refer to the technical manual for detailed steps and safety guidelines. Proper calibration is critical for ensuring the transmitter operates within specified accuracy and provides reliable gas detection. Failure to calibrate correctly may lead to inaccurate readings or system malfunctions. Always follow the recommended procedures to guarantee optimal performance and safety compliance.

4.4 Testing the System

Testing the system ensures all components function correctly after installation and configuration. Begin by verifying the power supply and checking for proper wiring connections; Activate the transmitter and monitor the LCD display for status indicators. Test alarm levels by simulating gas concentrations or using test gases to trigger alarms. Ensure relay outputs activate as configured. Perform a full system cycle, including zero and span calibration verification. Check for any error codes or abnormal readings. If issues arise, consult the troubleshooting guide in the manual. Document the test results for future reference. Testing confirms the system’s readiness for safe and reliable operation, ensuring compliance with safety standards and optimal performance in detecting gas hazards. Regular testing is crucial for maintaining system integrity and user confidence. Always follow the manufacturer’s test procedures for accurate results.

Maintenance and Troubleshooting

Regular maintenance ensures optimal performance. Clean sensors, check wiring, and verify grounding. Troubleshoot issues like sensor failure or wiring faults using diagnostic tools. Refer to the troubleshooting guide for solutions or contact technical support for assistance.

5.1 Routine Maintenance and Checks

Regular maintenance is essential to ensure the XNX transmitter operates efficiently and safely. Start with a visual inspection of the transmitter and sensor for any signs of damage or contamination. Clean the sensor and transmitter housing as needed, following the manufacturer’s guidelines; Check all wiring connections to ensure they are secure and free from damage. Verify that the grounding system is intact and functioning correctly to maintain intrinsic safety. Test the transmitter’s alarm levels and relay outputs to confirm proper functionality. Replace any worn or damaged components promptly. Use only certified tools and materials, such as M25 cable glands, to avoid compromising the system’s integrity. Schedule routine calibrations and performance tests as specified in the technical manual to maintain accuracy and reliability; Always refer to the troubleshooting guide if issues arise during maintenance.

5.2 Replacing the Sensor

Replacing the sensor in the XNX transmitter is a critical task that requires careful execution to ensure system accuracy and safety. Start by powering down the transmitter and disconnecting the power supply to avoid any electrical hazards. Next, disconnect the sensor from the transmitter by releasing the cable gland and separating the connector. Remove the old sensor from its mounting bracket, taking note of any specific alignment or positioning requirements. Install the new sensor, ensuring it is securely fastened and properly seated in the bracket. Reconnect the sensor to the transmitter, making sure all connections are tight and secure. Verify the sensor grounding to maintain intrinsic safety standards. Finally, refer to Section 4.1 to configure the transmitter for the new sensor type and range. Always use certified Honeywell Analytics sensors and follow the technical manual for specific instructions. Dispose of the old sensor according to local regulations and guidelines.

5.3 Diagnosing Common Issues

Troubleshooting the XNX transmitter involves identifying and resolving common issues promptly to ensure optimal performance. Start by checking the power supply connections and verifying that the transmitter is properly grounded. If the display is unresponsive, ensure the power source is operational and that all cables are securely connected. For sensor-related issues, review the configuration settings in Section 4.1 to confirm compatibility with the installed sensor type. Inspect the wiring and connections for any signs of damage or corrosion, especially in harsh environments. If alarms fail to trigger, verify that relay outputs are correctly configured in Section 4.2. For persistent problems, consult the troubleshooting guide in Appendix 7.3 or refer to the technical manual for detailed diagnostic procedures. Always ensure compliance with safety guidelines when performing diagnostics.

Compliance and Certification

The XNX transmitter complies with international safety standards, including ATEX, IECEx, and UL certifications, ensuring safe and reliable operation in hazardous environments.

6.1 Regulatory Compliance and Standards

The XNX Universal Transmitter adheres to global regulatory requirements, ensuring safety and performance across various regions. It meets ATEX and IECEx standards for use in explosive atmospheres, as well as UL certifications for North American markets. Compliance with these standards guarantees the transmitter’s reliability in hazardous environments. Proper installation following local regulations is essential to maintain compliance and ensure operational safety. The transmitter’s design incorporates intrinsic safety features, aligning with international codes for gas detection systems. Users must refer to the technical manual for specific compliance details and regional certifications, ensuring all installations meet the required safety standards. This adherence to regulations makes the XNX a trusted solution for industrial gas detection worldwide.

6.2 Certifications and Approvals

The XNX Universal Transmitter holds multiple certifications, ensuring its suitability for global industrial applications. It is certified to ISO 9001:2015 for quality management and ISO 14001:2015 for environmental management. Additionally, the transmitter complies with NEMA 4X standards, guaranteeing durability in harsh environments. Its design and manufacturing process are audited to meet rigorous industry benchmarks, ensuring reliability and performance. The XNX also holds approvals from recognized bodies for explosion-proof and flameproof installations. These certifications confirm the transmitter’s adherence to international safety and quality standards, making it a reliable choice for gas detection systems worldwide. Users can trust the XNX to operate safely and efficiently under various regulatory frameworks.

Appendices

This section provides supplementary materials, including technical specifications, a glossary of terms, and a troubleshooting guide to support transmitter installation and operation effectively.

7.1 Technical Specifications

The XNX Universal Transmitter is designed to operate with a wide range of gas sensing technologies, supporting both toxic and flammable gas detection. It features a 4-20mA analog output, relay outputs, and optional Modbus communication for seamless integration into industrial systems. The transmitter is compatible with Honeywell Analytics’ full portfolio of gas sensors, including catalytic bead, electrochemical, and infrared technologies. It operates on a 24V DC power supply, with optional configurations for multiple transmitters connected to a single power source. The device is housed in a durable, explosion-proof enclosure, meeting global certifications such as ATEX, UL, and CSA. Environmental operating conditions include a temperature range of -40°C to +60°C and an IP66 rating for dust and water ingress protection. Five threaded ports provide flexibility for sensor and cable connections, ensuring reliable performance in harsh industrial environments.

7.2 Glossary of Terms

This section provides definitions for key terms related to the XNX Transmitter to ensure clarity during installation and operation.

- 4-20mA Output: A standard analog signal range used to transmit gas concentration levels from the transmitter to a control system.

- Gas Sensing Technologies: Includes catalytic bead, electrochemical, and infrared sensors used for detecting toxic or flammable gases.

- Intrinsic Safety: A design feature ensuring the transmitter operates safely in hazardous environments by limiting energy levels to prevent ignition.

- Modbus Communication: A protocol enabling digital communication between the transmitter and control systems for advanced configuration and monitoring;

- Relay Outputs: Used to trigger alarms or shutdowns when preset gas levels are exceeded, ensuring safety in industrial settings.

Understanding these terms is essential for proper installation, configuration, and maintenance of the XNX Universal Transmitter.

7.3 Troubleshooting Guide

This section helps resolve common issues during the installation, configuration, or operation of the XNX Transmitter.

- Error Codes: Refer to the technical manual for specific error code meanings and resolution steps.

- Sensor Malfunction: Ensure the sensor is properly connected and calibrated. Check for environmental interference or damage.

- Communication Issues: Verify wiring connections and ensure the transmitter is configured correctly for Modbus or other protocols.

- Power Supply Problems: Confirm the power supply matches the transmitter’s requirements and check for loose connections.

- Alarm Relays Not Triggering: Test relay outputs and ensure alarm levels are correctly set.

Regular maintenance and adherence to safety guidelines can prevent many issues. Always consult the manual for detailed troubleshooting procedures.