COFFEE PROCESSING METHODS Coffee Cartel Processing coffee is a big thing, and it’s extremely important in determining how the coffee comes out as a finish product. We use the word “processing” to refer to every stage of the coffee making process – from harvesting the coffee cherries by hand-picking them off the plant, to the time when the coffee

Post-harvest Processing and Quality Assurance for

Washed Natural Honey Coffee Processing 101 Perfect. Handbook of Coffee Processing By-Products: Sustainable Applications presents alternative and sustainable solutions for coffee processing by-products and specifies their industrial potential, both as a source for the recovery of bioactive compounds and their reutilization in the pharmaceutical, biotechnological, food, biotechnology, and cosmetic, Processing is another of the most important contributors to coffee’s flavor. A simple description of the coffee processing is to remove coffee beans from the coffee fruit, dry them, and prepare them for shipment. But it’s done differently in different parts of the world, and each method produces coffee with unique flavor characteristics..

Tea Processing Tea Processing All teas start with plucking fresh leaves. The young leaves of the tea bush are hand-plucked to select only the finest quality leaf-grade teas. With a few exceptions all Peet’s teas are “fine-plucked”. Fine plucking is the practice of taking only Inconsistencies and poor practices during processing and drying of coffee were noted during the 2006 harvest in a coffee producing area in the highlands of the province of Veraguas. Since coffee quality depends on environmental conditions, cultivar, careful processing, and sufficient drying, these inconsistencies may disqualify a product with

The coffee beans, still sticky (like honey) with mucilage, are stored to ferment for 1-3 days. Here’s where things can get complicated. The Confusing Naming Process While we’re talking about the general honey process, there are subcategories that deserve mentioning: yellow, red, and black honey. Coffee hulling occurs during the initial stage of green coffee processing; it is usually done between pre-cleaning and size grading. The hulling process removes the parchment skin from the coffee bean. The process is carried out very gentle at low temperature. HULLING AND POLISHING Polishing is an optional process where any silver skin that remains

Coffee Industry Coffee is the world’s most valuable agricultural commodity. The coffee industry in the United States, and around the world, has exploded in recent years. Instead of simply drinking caffeinated and decaffeinated, coffee consumers are trying different types of coffee, such as, cappuccino, espresso, mocha, and latte. Consumer Wet processing, on the other hand, is used for arabica and results in so-called mild coffee, when fermentation is included in the preparation process. Dry processing is very simple and, most important of all, is less demanding in respect of harvesting, since all …

Main Content (use access key 5 to view full text / OCR mode) Wet processing, on the other hand, is used for arabica and results in so-called mild coffee, when fermentation is included in the preparation process. Dry processing is very simple and, most important of all, is less demanding in respect of harvesting, since all …

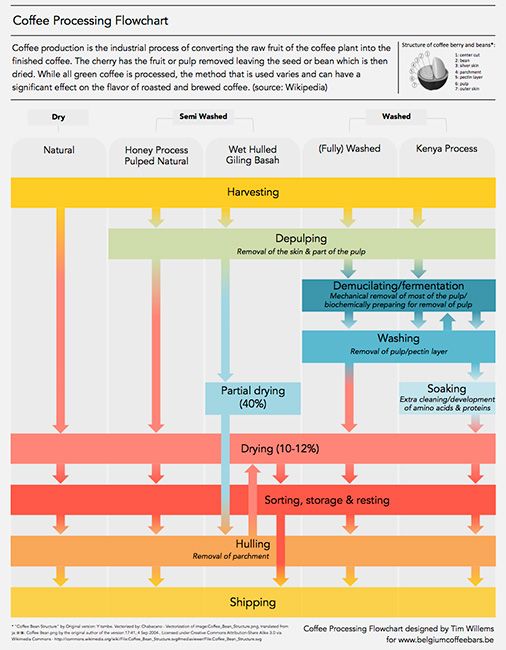

Main Content (use access key 5 to view full text / OCR mode) Coffee production is the industrial process of converting the raw fruit of the coffee plant into the finished coffee.The coffee cherry has the fruit or pulp removed leaving the seed or bean which is then dried. While all green coffee is processed, the method that is used varies and can have a significant effect on the flavor of roasted and brewed coffee.

Once the coffee is harvested, the real work starts: processing. Processing coffee is the act of removing the layers of skin, pulp, mucilage, and parchment that surround a coffee bean—the raw ingredient that the farmer will sell. How a grower chooses to process the coffee will have a profound impact on how that coffee … coffee cherries 5.5 to 6kg coffee harvesting dry processing wet processing green beans separation drying hulling cleaning grading polishing sorting bagging separation demucilaging pulping sucden sucden coffee process flowchart

The coffee beans, still sticky (like honey) with mucilage, are stored to ferment for 1-3 days. Here’s where things can get complicated. The Confusing Naming Process While we’re talking about the general honey process, there are subcategories that deserve mentioning: yellow, red, and black honey. Processing is another of the most important contributors to coffee’s flavor. A simple description of the coffee processing is to remove coffee beans from the coffee fruit, dry them, and prepare them for shipment. But it’s done differently in different parts of the world, and each method produces coffee with unique flavor characteristics.

The coffee beans, still sticky (like honey) with mucilage, are stored to ferment for 1-3 days. Here’s where things can get complicated. The Confusing Naming Process While we’re talking about the general honey process, there are subcategories that deserve mentioning: yellow, red, and black honey. Main Content (use access key 5 to view full text / OCR mode)

Jul 27, 2004 · “This comprehensive and practical book covers the cultivation, processing and sustainable production of coffee…” (Food Science & Technology Abstracts, Vol. 37 (7), 2005) “…provides a good understanding of the technologies which have been responsible for increasing coffee … Coffee In France Late 1600s - Coffee reaches Paris, and coffee houses begin to appear 1710 - An infusion brewing process is developed 1713 - King Louis XIV’s court is the first to add sugar to coffee 1723 - French naval officers introduce coffee plantations to the Americas

COFFEE PROCESSING AT THE FARM LEVEL, An Ecological and Profitable Case 2 efficient way, into products of trade value, represented by organic manure and animal protein. The technology that was introduced commercially only in 1996 is already being used in Jun 07, 2016 · Coffee Processing Technology. • Dutch began to grow coffee in the Malabar region. • British led to set up Arabica coffee plantations across the hilly regions in South India. MAJOR COFFEE PRODUCING COUNTRIES 1 .Brazil 2.Vietnam 3.Colombia 4 .Indonesia 5 .Ethiopia 6. MAJOR COFFEE CONSUMING COUNTRIES 1 .Finland 2.

The study points out that luwak coffee processing tend to produce green bean with pale yellow colour, and caffeine contents (1.08-1.24%) which ensure that Asian civet has eaten Arabica varieties. Processing is another of the most important contributors to coffee’s flavor. A simple description of the coffee processing is to remove coffee beans from the coffee fruit, dry them, and prepare them for shipment. But it’s done differently in different parts of the world, and each method produces coffee with unique flavor characteristics.

Methods of Coffee Processing

Instant coffee plant Diagram SPX FLOW. The study points out that luwak coffee processing tend to produce green bean with pale yellow colour, and caffeine contents (1.08-1.24%) which ensure that Asian civet has eaten Arabica varieties., Wet processing, on the other hand, is used for arabica and results in so-called mild coffee, when fermentation is included in the preparation process. Dry processing is very simple and, most important of all, is less demanding in respect of harvesting, since all ….

Coffee Processing Methods What You Should Know. Coffee production is the industrial process of converting the raw fruit of the coffee plant into the finished coffee.The coffee cherry has the fruit or pulp removed leaving the seed or bean which is then dried. While all green coffee is processed, the method that is used varies and can have a significant effect on the flavor of roasted and brewed coffee., Methods of Coffee Processing After coffee is harvested, it undergoes a processing method in which the coffee beans are removed from the raw fruit. There are various techniques of processing coffee; each technique impacts the final flavor of the end product..

Processing Coffee Fruit Removal and Drying CoffeeReview.com

COFFEE BEAN PROCESSING Solex Thermal Sciences. Wet processing is generally regarded as producing a higher quality coffee and commands a significant premium over unwashed coffee at the export level- 20% higher (Minten et.al., 2014). However, even when there are seemingly significant price premiums for washed coffee, only about 30% of Ethiopia’s coffee export is washed and both the https://simple.wikipedia.org/wiki/Cacao_tree Gentle processing, including steam stripping, assures premium aroma extraction. An aroma recovery system is available to recover valuable aromas before concentration process. A further separation process further enhances the quality of the final coffee by removing вЂoff-flavours’ of extract..

Handbook of Coffee Processing By-Products: Sustainable Applications presents alternative and sustainable solutions for coffee processing by-products and specifies their industrial potential, both as a source for the recovery of bioactive compounds and their reutilization in the pharmaceutical, biotechnological, food, biotechnology, and cosmetic coffee if small enough while larger plantations or processing stations will need to use kilns to speed up the process. The dry or natural method uses far fewer resources to process the coffee beans. The harvested cherries are allowed to dry with the fruit on the beans on terraces or on waist high netting to ensure even drying.

Aug 15, 2017 · The coffee cherry’s skin is removed, as in wet processing, but instead of soaking the cherry, they’re spread out to dry with the pulp still attached to the beans. The result is a coffee with body and low acidity, like a natural, but without the telltale vivid fruits. Nevertheless, coffee silverskin (CS), spent coffee grounds (SCGs), coffee husks, and immature/defective coffee beans, the industrial by-products of coffee processing, have a potential use in skin-care formulations, based on their high content of bioactive compounds.

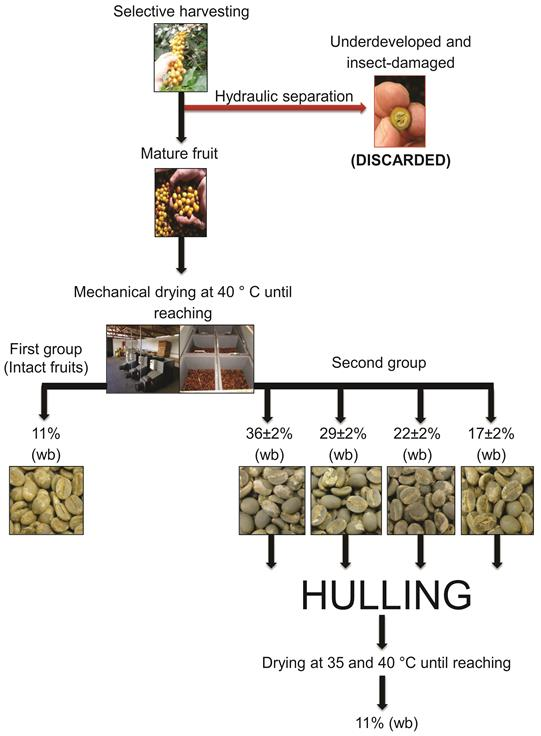

Targeted Study of the Arabica Coffee production Chain in North Sumatra (The Mandheling Coffee) North Sumatra Province is known as one of the Arabica producing center with the production of 15000 tons/year, accounting to 33.3% of the Indonesian Arabica production. There are three main districts in North Sumatra producing the coffee, Rao 2007). The processing of coffee initiates with the conversion of coffee cherries into green coffee beans, and starts with the removal of both the pulp and hull using either a wet or dry method. Depending on the method of coffee cherries processing, i.e., wet or dry process, the solid residues obtained have different terminologies: pulp or

sections will discuss the roast process and the similarities and differences of these roasters. 3.1 The roast pro cess A schematic drawing in appendix A.1 represent the pilot roaster. This drawing can also be used to describe to roast proces of the industrial roaster. The following part will help to understand the process. Coffee hulling occurs during the initial stage of green coffee processing; it is usually done between pre-cleaning and size grading. The hulling process removes the parchment skin from the coffee bean. The process is carried out very gentle at low temperature. HULLING AND POLISHING Polishing is an optional process where any silver skin that remains

The Dry Method. In this, the oldest of processing methods, the coffee fruit is simply picked and put out into the sun to dry, fruit and all. It is spread in a thin layer and raked regularly to maintain even temperatures from top to bottom of the layer. Drying takes anywhere from ten days to three Post-harvest Processing and Quality Assurance for Speciality/Organic Coffee Products Alastair Hicks FAO Regional Office for Asia and the Pacific Bangkok, Thailand Abstract This paper covers the post-harvest aspects, processing and quality assurance for speciality/organic coffee products. It starts with the origins of coffee, what aspects

Coffee processing equipment, coffee production, and information about coffee pulping, drying, and fermentation methods. Coffee Processing Irrespective of the harvesting method, green coffee beans and overripe coffee cherries inevitably end up mixed with the perfectly ripe cherries and must be separated during coffee processing. Methods of Coffee Processing After coffee is harvested, it undergoes a processing method in which the coffee beans are removed from the raw fruit. There are various techniques of processing coffee; each technique impacts the final flavor of the end product.

Wet processing is generally regarded as producing a higher quality coffee and commands a significant premium over unwashed coffee at the export level- 20% higher (Minten et.al., 2014). However, even when there are seemingly significant price premiums for washed coffee, only about 30% of Ethiopia’s coffee export is washed and both the The coffee cultivation process begins with a coffee cherry. Coffee cherries are differentiated by type and natural conditions such as altitude, latitude, and volcanic soil. A coffee plant usually starts to produce flowers 3–4 years after it is planted, and it is from these flowers that coffee …

Processing coffee is a big thing, and it’s extremely important in determining how the coffee comes out as a finish product. We use the word “processing” to refer to every stage of the coffee making process – from harvesting the coffee cherries by hand-picking them off the plant, to the time when the coffee The average arabica coffee plant is a massive bush with dark-green oval leaves. The fruits are also oval and contain two flat seeds. Arabica coffee represents about 70% of total world production. Robusta coffee (Coffea canephora) produces beans which are generally blended with arabica to increase the flavour and body of the resulting coffee

The study points out that luwak coffee processing tend to produce green bean with pale yellow colour, and caffeine contents (1.08-1.24%) which ensure that Asian civet has eaten Arabica varieties. Coffee Industry Coffee is the world’s most valuable agricultural commodity. The coffee industry in the United States, and around the world, has exploded in recent years. Instead of simply drinking caffeinated and decaffeinated, coffee consumers are trying different types of coffee, such as, cappuccino, espresso, mocha, and latte. Consumer

The average arabica coffee plant is a massive bush with dark-green oval leaves. The fruits are also oval and contain two flat seeds. Arabica coffee represents about 70% of total world production. Robusta coffee (Coffea canephora) produces beans which are generally blended with arabica to increase the flavour and body of the resulting coffee sections will discuss the roast process and the similarities and differences of these roasters. 3.1 The roast pro cess A schematic drawing in appendix A.1 represent the pilot roaster. This drawing can also be used to describe to roast proces of the industrial roaster. The following part will help to understand the process.

Jan 31, 2010 · Coffee: Growing, Processing, Sustainable Production [Jean Nicolas Wintgens] on Amazon.com. *FREE* shipping on qualifying offers. An outstanding and currently the only comprehensive handbook for the coffee-professional. 40 authors from the leading coffee-growing countries present the most recent technologies applied to coffee husbandry. The book features 900 carefully selected … Post-harvest Processing and Quality Assurance for Speciality/Organic Coffee Products Alastair Hicks FAO Regional Office for Asia and the Pacific Bangkok, Thailand Abstract This paper covers the post-harvest aspects, processing and quality assurance for speciality/organic coffee products. It starts with the origins of coffee, what aspects

Coffee production Wikipedia

Coffee processing technology v.1. Full View. Structure of the Coffee Fruit Since there is a great deal of terminology which grows out of certain character istics of the coffee fruit, and since the steps in both harvesting and processing arise out of the structure of the berry, it is believed a brief description of the fruit itself would be of value here., Cimbria designs and manufactures machines and equipment for green coffee processing to the highest engineering qualities and standards. In-depth product knowledge and expertise in the most modern processing technology and plant design ensure optimum processing of your coffee ….

Post-harvest Processing and Quality Assurance for

Methods of Coffee Processing. There are two ways coffee can be processed - dry ('natural') processing and wet ('fermented and washed') processing. In most cases, wet processing is regarded as producing a higher quality product. However, some areas prefer dry processed coffee for its 'fuller' flavour., Assessing and prescribing fertilizer use is critical to profitable and sustainable coffee production, and this is becoming a priority concern for the Robusta coffee industry..

These coffee processing methods use a combination of wet and dry processing methods to combine the benefits of both. Generally, the coffee cherries go through the first step of wet processing, where the fruit and skin are removed. Coffee hulling occurs during the initial stage of green coffee processing; it is usually done between pre-cleaning and size grading. The hulling process removes the parchment skin from the coffee bean. The process is carried out very gentle at low temperature. HULLING AND POLISHING Polishing is an optional process where any silver skin that remains

These coffee processing methods use a combination of wet and dry processing methods to combine the benefits of both. Generally, the coffee cherries go through the first step of wet processing, where the fruit and skin are removed. Jun 07, 2016 · Coffee Processing Technology. • Dutch began to grow coffee in the Malabar region. • British led to set up Arabica coffee plantations across the hilly regions in South India. MAJOR COFFEE PRODUCING COUNTRIES 1 .Brazil 2.Vietnam 3.Colombia 4 .Indonesia 5 .Ethiopia 6. MAJOR COFFEE CONSUMING COUNTRIES 1 .Finland 2.

Jan 31, 2010 · Coffee: Growing, Processing, Sustainable Production [Jean Nicolas Wintgens] on Amazon.com. *FREE* shipping on qualifying offers. An outstanding and currently the only comprehensive handbook for the coffee-professional. 40 authors from the leading coffee-growing countries present the most recent technologies applied to coffee husbandry. The book features 900 carefully selected … Wet processing is generally regarded as producing a higher quality coffee and commands a significant premium over unwashed coffee at the export level- 20% higher (Minten et.al., 2014). However, even when there are seemingly significant price premiums for washed coffee, only about 30% of Ethiopia’s coffee export is washed and both the

Coffee processing equipment, coffee production, and information about coffee pulping, drying, and fermentation methods. Coffee Processing Irrespective of the harvesting method, green coffee beans and overripe coffee cherries inevitably end up mixed with the perfectly ripe cherries and must be separated during coffee processing. The average arabica coffee plant is a massive bush with dark-green oval leaves. The fruits are also oval and contain two flat seeds. Arabica coffee represents about 70% of total world production. Robusta coffee (Coffea canephora) produces beans which are generally blended with arabica to increase the flavour and body of the resulting coffee

Inconsistencies and poor practices during processing and drying of coffee were noted during the 2006 harvest in a coffee producing area in the highlands of the province of Veraguas. Since coffee quality depends on environmental conditions, cultivar, careful processing, and sufficient drying, these inconsistencies may disqualify a product with coffee if small enough while larger plantations or processing stations will need to use kilns to speed up the process. The dry or natural method uses far fewer resources to process the coffee beans. The harvested cherries are allowed to dry with the fruit on the beans on terraces or on waist high netting to ensure even drying.

Aug 27, 2014 · Honey Process – skin and pulp are removed, but some or all of the mucilage (Honey) remains. Washed Process – skin, pulp, and mucilage are removed using water and fermentation. Also called Fully Washed. This is the conventional form of Arabica coffee processing … The Dry Method. In this, the oldest of processing methods, the coffee fruit is simply picked and put out into the sun to dry, fruit and all. It is spread in a thin layer and raked regularly to maintain even temperatures from top to bottom of the layer. Drying takes anywhere from ten days to three

Coffee production is the industrial process of converting the raw fruit of the coffee plant into the finished coffee.The coffee cherry has the fruit or pulp removed leaving the seed or bean which is then dried. While all green coffee is processed, the method that is used varies and can have a significant effect on the flavor of roasted and brewed coffee. Aug 15, 2017 · The coffee cherry’s skin is removed, as in wet processing, but instead of soaking the cherry, they’re spread out to dry with the pulp still attached to the beans. The result is a coffee with body and low acidity, like a natural, but without the telltale vivid fruits.

Structure of the Coffee Fruit Since there is a great deal of terminology which grows out of certain characterВ istics of the coffee fruit, and since the steps in both harvesting and processing arise out of the structure of the berry, it is believed a brief description of the fruit itself would be of value here. Gentle processing, including steam stripping, assures premium aroma extraction. An aroma recovery system is available to recover valuable aromas before concentration process. A further separation process further enhances the quality of the final coffee by removing вЂoff-flavours’ of extract.

ready for drying. The coffee drying process can be completed on large tables or beds in the sun, as with the dry method, or by using large mechanical tumblers or other machinery. The next step in coffee bean processing is milling. Once the coffee beans are dried to a moisture content no higher than Once the coffee is harvested, the real work starts: processing. Processing coffee is the act of removing the layers of skin, pulp, mucilage, and parchment that surround a coffee bean—the raw ingredient that the farmer will sell. How a grower chooses to process the coffee will have a profound impact on how that coffee …

The study points out that luwak coffee processing tend to produce green bean with pale yellow colour, and caffeine contents (1.08-1.24%) which ensure that Asian civet has eaten Arabica varieties. Rao 2007). The processing of coffee initiates with the conversion of coffee cherries into green coffee beans, and starts with the removal of both the pulp and hull using either a wet or dry method. Depending on the method of coffee cherries processing, i.e., wet or dry process, the solid residues obtained have different terminologies: pulp or

Structure of the Coffee Fruit Since there is a great deal of terminology which grows out of certain character istics of the coffee fruit, and since the steps in both harvesting and processing arise out of the structure of the berry, it is believed a brief description of the fruit itself would be of value here. Coffee Industry Coffee is the world’s most valuable agricultural commodity. The coffee industry in the United States, and around the world, has exploded in recent years. Instead of simply drinking caffeinated and decaffeinated, coffee consumers are trying different types of coffee, such as, cappuccino, espresso, mocha, and latte. Consumer

Coffee Processing Methods Espresso & Coffee Guide. Coffee In France Late 1600s - Coffee reaches Paris, and coffee houses begin to appear 1710 - An infusion brewing process is developed 1713 - King Louis XIV’s court is the first to add sugar to coffee 1723 - French naval officers introduce coffee plantations to the Americas, Methods of Coffee Processing After coffee is harvested, it undergoes a processing method in which the coffee beans are removed from the raw fruit. There are various techniques of processing coffee; each technique impacts the final flavor of the end product..

The Basics of Coffee Processing — Blue Bottle Coffee Lab

Coffee production Wikipedia. coffee if small enough while larger plantations or processing stations will need to use kilns to speed up the process. The dry or natural method uses far fewer resources to process the coffee beans. The harvested cherries are allowed to dry with the fruit on the beans on terraces or on waist high netting to ensure even drying., ready for drying. The coffee drying process can be completed on large tables or beds in the sun, as with the dry method, or by using large mechanical tumblers or other machinery. The next step in coffee bean processing is milling. Once the coffee beans are dried to a moisture content no higher than.

Coffee Processing Coffee - CoffeeResearch.org

Value Addition and Processing by Farmers in Developing. The study points out that luwak coffee processing tend to produce green bean with pale yellow colour, and caffeine contents (1.08-1.24%) which ensure that Asian civet has eaten Arabica varieties. https://it.wikipedia.org/wiki/Coffee_Lake Processing is another of the most important contributors to coffee’s flavor. A simple description of the coffee processing is to remove coffee beans from the coffee fruit, dry them, and prepare them for shipment. But it’s done differently in different parts of the world, and each method produces coffee with unique flavor characteristics..

Post-harvest Processing and Quality Assurance for Speciality/Organic Coffee Products Alastair Hicks FAO Regional Office for Asia and the Pacific Bangkok, Thailand Abstract This paper covers the post-harvest aspects, processing and quality assurance for speciality/organic coffee products. It starts with the origins of coffee, what aspects The coffee cultivation process begins with a coffee cherry. Coffee cherries are differentiated by type and natural conditions such as altitude, latitude, and volcanic soil. A coffee plant usually starts to produce flowers 3–4 years after it is planted, and it is from these flowers that coffee …

coffee if small enough while larger plantations or processing stations will need to use kilns to speed up the process. The dry or natural method uses far fewer resources to process the coffee beans. The harvested cherries are allowed to dry with the fruit on the beans on terraces or on waist high netting to ensure even drying. Cimbria designs and manufactures machines and equipment for green coffee processing to the highest engineering qualities and standards. In-depth product knowledge and expertise in the most modern processing technology and plant design ensure optimum processing of your coffee …

There are two ways coffee can be processed - dry ('natural') processing and wet ('fermented and washed') processing. In most cases, wet processing is regarded as producing a higher quality product. However, some areas prefer dry processed coffee for its 'fuller' flavour. Methods of Coffee Processing After coffee is harvested, it undergoes a processing method in which the coffee beans are removed from the raw fruit. There are various techniques of processing coffee; each technique impacts the final flavor of the end product.

Methods of Coffee Processing After coffee is harvested, it undergoes a processing method in which the coffee beans are removed from the raw fruit. There are various techniques of processing coffee; each technique impacts the final flavor of the end product. Coffee Industry Coffee is the world’s most valuable agricultural commodity. The coffee industry in the United States, and around the world, has exploded in recent years. Instead of simply drinking caffeinated and decaffeinated, coffee consumers are trying different types of coffee, such as, cappuccino, espresso, mocha, and latte. Consumer

Once the coffee is harvested, the real work starts: processing. Processing coffee is the act of removing the layers of skin, pulp, mucilage, and parchment that surround a coffee bean—the raw ingredient that the farmer will sell. How a grower chooses to process the coffee will have a profound impact on how that coffee … COFFEE PROCESSING AT THE FARM LEVEL, An Ecological and Profitable Case 2 efficient way, into products of trade value, represented by organic manure and animal protein. The technology that was introduced commercially only in 1996 is already being used in

Coffee production is the industrial process of converting the raw fruit of the coffee plant into the finished coffee.The coffee cherry has the fruit or pulp removed leaving the seed or bean which is then dried. While all green coffee is processed, the method that is used varies and can have a significant effect on the flavor of roasted and brewed coffee. Main Content (use access key 5 to view full text / OCR mode)

The Dry Method. In this, the oldest of processing methods, the coffee fruit is simply picked and put out into the sun to dry, fruit and all. It is spread in a thin layer and raked regularly to maintain even temperatures from top to bottom of the layer. Drying takes anywhere from ten days to three Coffee Industry Coffee is the world’s most valuable agricultural commodity. The coffee industry in the United States, and around the world, has exploded in recent years. Instead of simply drinking caffeinated and decaffeinated, coffee consumers are trying different types of coffee, such as, cappuccino, espresso, mocha, and latte. Consumer

Tea Processing Tea Processing All teas start with plucking fresh leaves. The young leaves of the tea bush are hand-plucked to select only the finest quality leaf-grade teas. With a few exceptions all Peet’s teas are “fine-plucked”. Fine plucking is the practice of taking only Coffee processing methods of the world’s top coffees is achieved by many different methods. These processing techniques can be grouped into four categories: Wet Processing (Washed), Dry Processing (Natural, Sun Dried), Pulped Natural Processing, and Semi-Washed Processing.

The average arabica coffee plant is a massive bush with dark-green oval leaves. The fruits are also oval and contain two flat seeds. Arabica coffee represents about 70% of total world production. Robusta coffee (Coffea canephora) produces beans which are generally blended with arabica to increase the flavour and body of the resulting coffee Targeted Study of the Arabica Coffee production Chain in North Sumatra (The Mandheling Coffee) North Sumatra Province is known as one of the Arabica producing center with the production of 15000 tons/year, accounting to 33.3% of the Indonesian Arabica production. There are three main districts in North Sumatra producing the coffee,

The coffee cultivation process begins with a coffee cherry. Coffee cherries are differentiated by type and natural conditions such as altitude, latitude, and volcanic soil. A coffee plant usually starts to produce flowers 3–4 years after it is planted, and it is from these flowers that coffee … Main Content (use access key 5 to view full text / OCR mode)

sections will discuss the roast process and the similarities and differences of these roasters. 3.1 The roast pro cess A schematic drawing in appendix A.1 represent the pilot roaster. This drawing can also be used to describe to roast proces of the industrial roaster. The following part will help to understand the process. The coffee cultivation process begins with a coffee cherry. Coffee cherries are differentiated by type and natural conditions such as altitude, latitude, and volcanic soil. A coffee plant usually starts to produce flowers 3–4 years after it is planted, and it is from these flowers that coffee …